VLAF/HLAF Clean Benches

LAF’S – Laminar Air Flow Units (LAFs) are devices that are designed to provide a clean environment (Class 100) to protect the product. However, they do not provide any protection to the worker. In LAFs units, the air flows in a uniform direction with a constant speed, with little to no crossover air streams. Airborne contamination is filtered through HEPA (filter 99.999% @ 0.3µm) or ULPA (99.999% @0.12µm) filters,providing the cleanest work area. However, it is important to note that air potentially contaminated with infectious agents may be blown toward the worker. Therefore, LAF should only be used for work with non-infectious materials such as media preparation. They should never be used with potentially infectious materials, toxins, volatile chemicals, or materials that may cause hypersensitivity in the worker.

PIOUS TrimGARD HORIZONTAL & VERTICAL LAMINAR AIR FLOW

- DESCRIPTION

- FEATURES

- WORKING PRINCIPLE

- MODELS

- ACCESSORIES

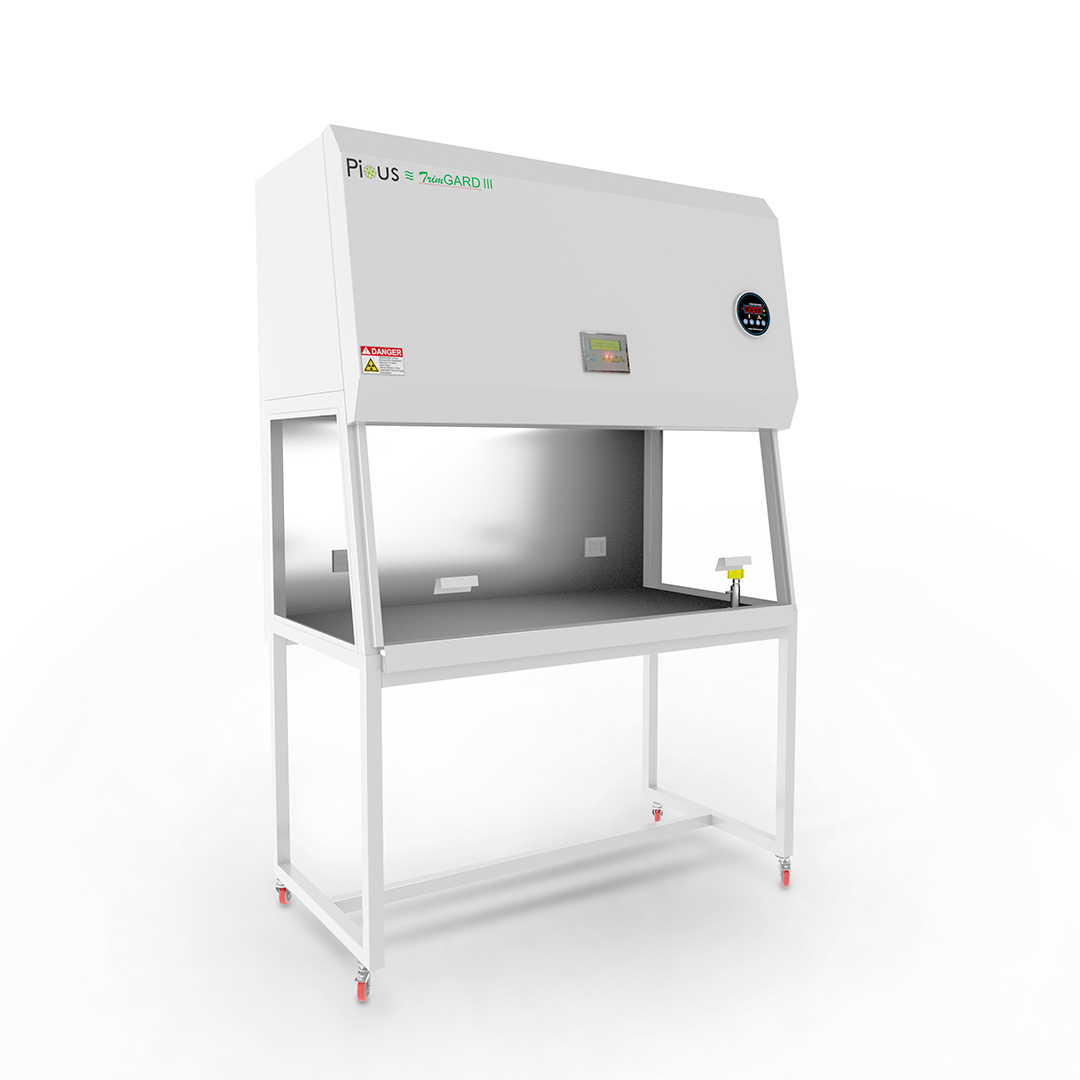

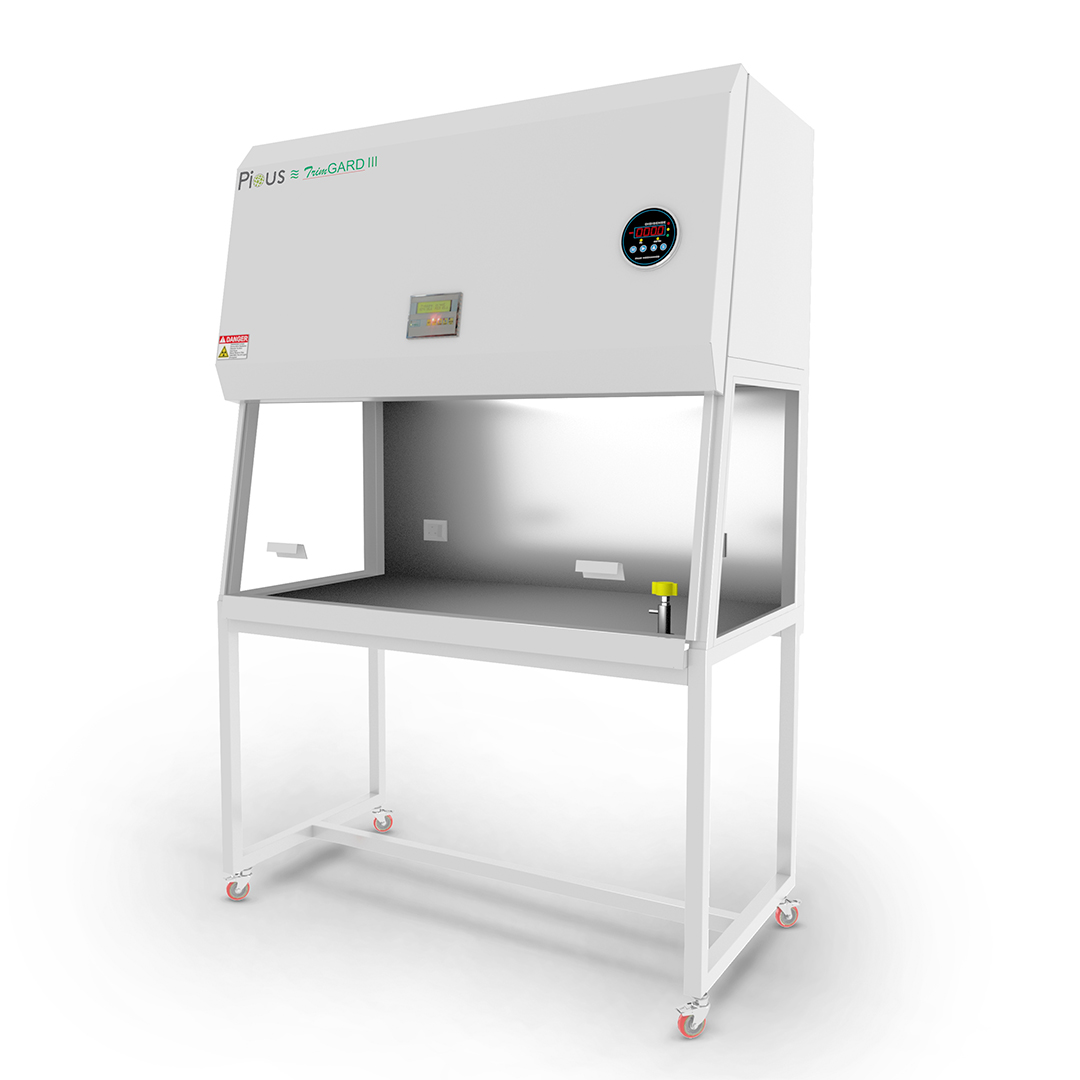

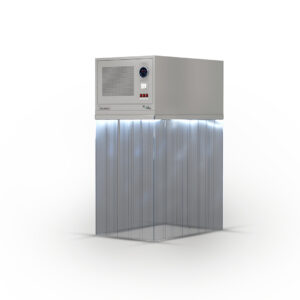

PIOUS TrimGARD HORIZONTAL & VERTICAL LAMINAR AIR FLOW clean benches, whether vertical or horizontal, are crucial tools in laboratory and cleanroom environments for creating controlled, sterile workspaces. Vertical laminar airflow benches feature a downward airflow pattern, filtering air through HEPA filters to remove contaminants and provide a clean environment for tasks such as specimen handling and delicate assembly work. On the other hand, horizontal laminar airflow benches direct airflow parallel to the work surface, creating a particle-free environment suitable for activities like tissue culture and microelectronics assembly. Both types offer transparent front openings for easy access while maintaining airflow integrity, with the choice between them depending on specific application requirements and space constraints.

Airflow: A constant and controlled flow of HEPA-filtered air is maintained within the cabinet to create a particle-free environment.

Containment: LAF cabinets are designed to prevent contamination from entering the work area, and to keep the work area isolated from the outside environment.

Illumination: LAF cabinets have built-in lighting to provide a bright and well-lit work surface.

Work Surface: The interior of the LAF cabinet is designed to accommodate work materials and equipment, and is often made of a material that is easy to clean and maintain.

Filter System: The LAF cabinet is equipped with a high-efficiency particulate air (HEPA) filter that removes particles from the airflow, ensuring that the interior of the cabinet remains particle-free.

Control Panel: LAF cabinets have an advanced Microcontroller controller and Touch Panel/HMI.

Electrical Outlets: Electrical outlets can be installed inside the cabinet to provide power to equipment and devices.

HEPA filter integrity testing capability: PAO injection port provision for HEPA filter integrity test.

Differential pressure across filter monitoring: Selection between Magnehelic gauge or digital display of differential pressure value across filters.

Gas Outlets: Gas outlets installed inside the cabinet to provide a source of nitrogen or other gases, which may be required for certain applications.

VLF: A Vertical Laminar Airflow Bench is laboratory equipment used for handling and manipulating samples in a sterile environment. It uses a laminar airflow system to create a flow of clean air that is directed over the work surface, effectively creating a “clean zone” free of particulates and other contaminants. This allows for the handling of sensitive samples, such as cell cultures or microorganisms, without the risk of contamination. The airflow is directed vertically, hence the name “vertical laminar airflow bench”.

HLF: A horizontal laminar airflow bench, also known as a horizontal laminar flow hood, is a type of laboratory equipment that utilizes horizontal laminar airflow technology to create a clean and controlled environment for work with sensitive materials. It typically consists of a work surface, a hood or enclosure, and a fan and filter unit. The fan pulls air through the filters, which remove particles and contaminants and then blows the filtered air horizontally across the work surface. This creates a smooth and uniform flow of clean air that helps to prevent contaminants from entering the work area. Horizontal laminar airflow benches are commonly used in laboratory research, pharmaceutical manufacturing, and semiconductor manufacturing, among other applications, to protect samples, cultures, and delicate electronic devices from contamination.

VLF

Model Code | Internal Width (mm) | Internal Depth (mm) | Internal Height(mm) |

402 | 1300 | 610 | 610 |

502 | 1600 | 610 | 610 |

602 | 1900 | 610 | 610 |

Customized sizes Available as per requirement | |||

Model Code | External Width (mm) | External Depth(mm) | External Height(mm) |

402 | 1380 | 645 | 1990 |

502 | 1680 | 645 | 1990 |

602 | 1980 | 645 | 1990 |

Customized sizes Available as per requirement | |||

HLF

Model Code | Internal Width (mm) | Internal Depth (mm) | Internal Height(mm) |

302 | 880 | 610 | 585 |

402 | 1185 | 610 | 585 |

502 | 1490 | 610 | 585 |

602 | 1794 | 610 | 585 |

Customized sizes Available as per requirement | |||

Model Code | External Width (mm) | External Depth(mm) | External Height(mm) |

302 | 995 | 1035 | 1500 |

402 | 1300 | 1035 | 1500 |

502 | 1605 | 1035 | 1500 |

602 | 1910 | 1035 | 1500 |

Customized sizes Available as per requirement | |||

UV Light: Ultraviolet (UV) lights can be installed inside the hood to kill bacteria and other microorganisms.

Glass Sash at Front: A glass sash can be installed at the front of the hood to provide protection to the user from exposure to the UV light during the decontamination cycle.

Fully SS Body for GMP Models: For applications that require compliance with Good Manufacturing Practices (GMP), a fully stainless steel body can be used for the hood.

Velocity Sensor: A velocity sensor can be used to monitor and control the flow of air inside the hood.

EC Blowers: Energy-efficient EC blowers can be used to maintain a constant and controlled flow of air inside the hood.

These accessories can be customized and integrated into the Laminar Flow Hood to meet the specific requirements of the user and the application