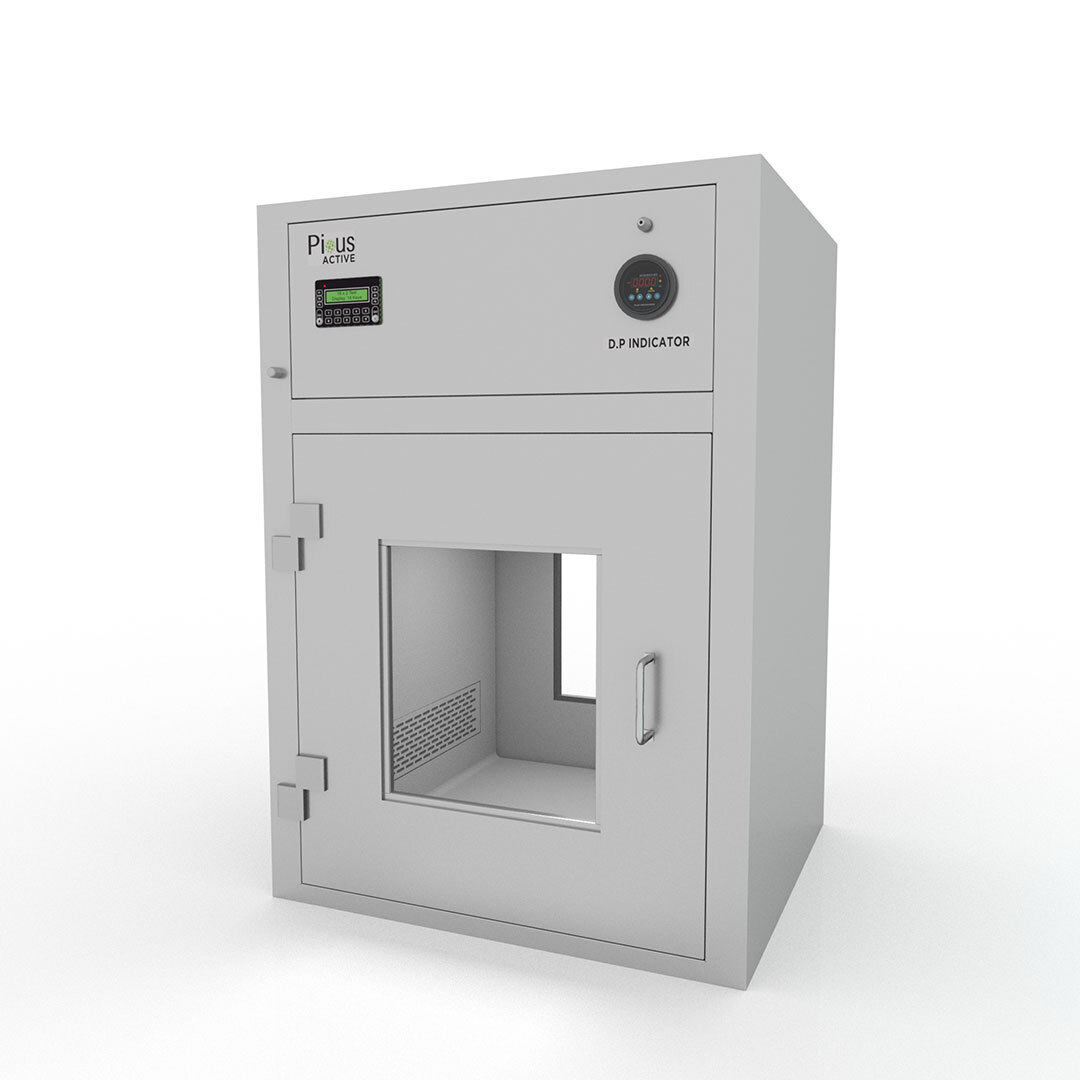

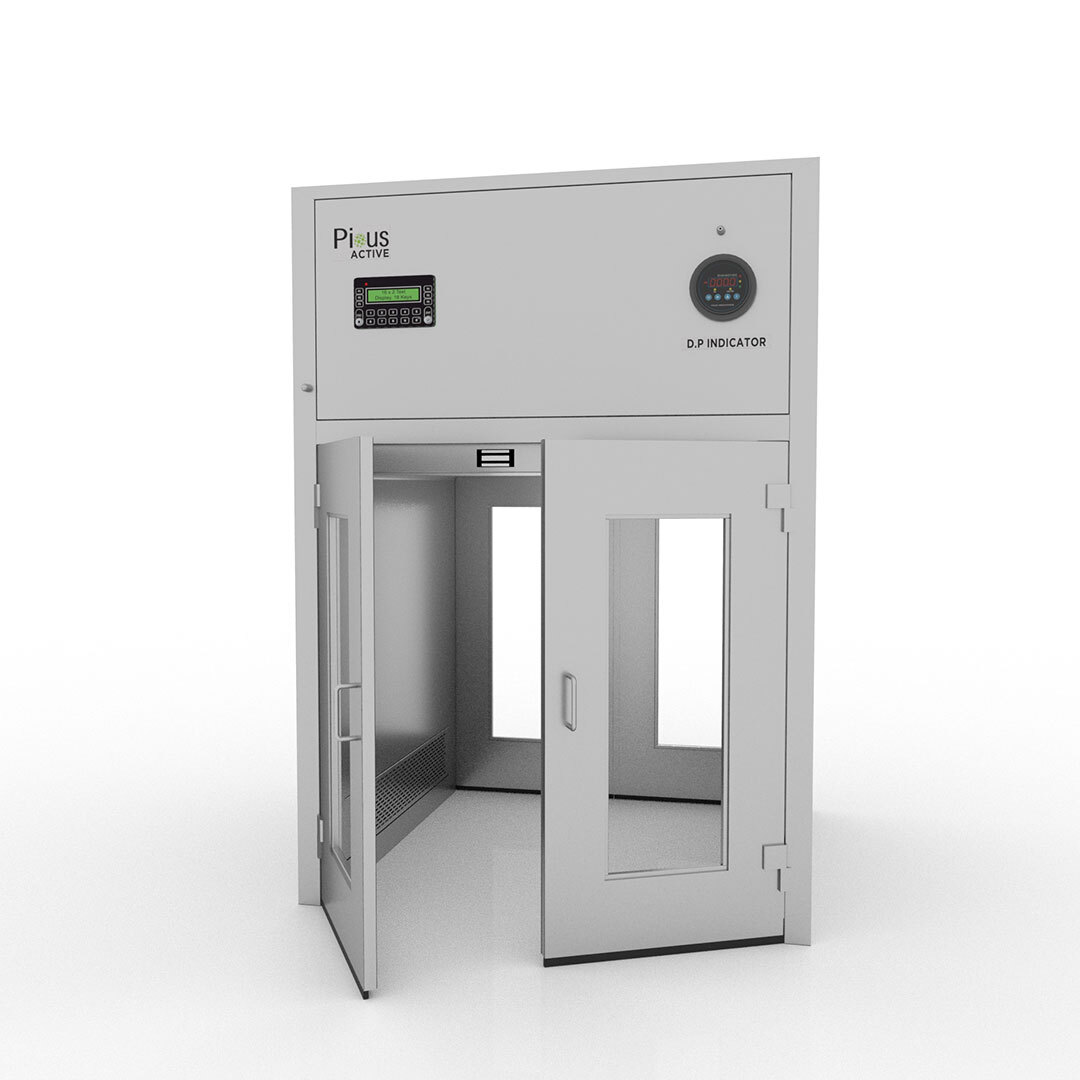

Dynamic Pass Box

Dynamic Pass Box – is a barrier between two areas with different sterility. It allows material transfer between areas with different sterility without cross-contamination of air. To separate the areas Dynamic Pass Box uses High Chamber pressure and techniques of door interlocking. Also, it is available in a wide range of chamber sizes and shapes like L type and 3- way. The Dynamic pass box is provided with Two-stage filtration: Pre-filter, Fresh air filter, and HEPA Filter. The Pre-filter, Final Filter, Digital Gauge, and Blower with Motor are installed inside the panel. Glass view panels on the doors are available to have a vision of the material inside the chamber. The basic purpose of this equipment/ system is to provide ISO Class 5 (Class 100) Airflow in the workspace. The units are designed to deliver air in the Vertical – Recirculation system

PIOUS Model ____ACTIVE – Elevating Clean Transfers

- DESCRIPTION

- FEATURES

- WORKING PRINCIPLE

- MODELS

- ACCESSORIES

The PIOUS ACTIVE Dynamic Pass Box Acts as a crucial barrier between areas of differing sterility levels, ensuring the safe transfer of materials without air cross-contamination. This advanced solution employs high chamber pressure and door interlocking techniques for effective segregation. Available in various chamber sizes and configurations, it features a two-stage filtration system, including pre-filters, fresh air filters, and HEPA filters, along with essential components like digital gauges and blowers with motors inside the panel. Glass view panels on the doors provide visibility, and the unit maintains ISO Class 5 (Class 100) airflow through a vertical recirculation system, making it an ideal choice for maintaining sterility during material transfers.

Two Stage filtration with a recirculation System : The re-circulatory air system and air intake keep the dynamic pass box under positive pressure. It includes an EU 14 HEPA filter of around 0.3 microns with an efficiency of 99.999% and an EU 5 Pre-filter of 5 microns with an air velocity of 0.45m/sec (90 ft. /min).

System designed For the transfer of materials between classified areas or between a classified area and a non-classified area, with decontamination through air-sweeping HEPA filters. The unit is equipped with a ventilation system coupled with air filtration to ensure a clean environment ISO Class 5 inside the chamber before the opening of the door. Vertical purging removes any trace contaminants that could enter the cleanroom environment. The unit operates with a recirculating airflow with the help of an internal blower, which means no external ducting is required.

Model Code | Internal Width (mm) | Internal Depth (mm) | Internal Height(mm) |

Active 5.5.5 | 450 | 450 | 450 |

Active 6.6.6 | 600 | 600 | 600 |

Active 9.9.9 | 900 | 900 | 900 |

Active 10.10.10 | 1000 | 1000 | 1000 |

Model Code | External Width (mm) | External Depth (mm) | External Height(mm) |

Active 5.5.5 | 600 | 520 | 900 |

Active 6.6.6 | 650 | 670 | 1050 |

Active 9.9.9 | 1050 | 970 | 1350 |

Active 10.10.10 | 1150 | 1070 | 1450 |

Customized sizes Available as per requirement | |||

Support Stand or Base Box: Provides stable foundation and support for equipment.

Floor-Mounted Construction with Three Side Wall Structures & Door Drop Seal: Ensures a robust build with three-sided walls and a sealed door for enhanced structural integrity.

Internal Shelves: Offers organized storage space within the equipment.

Buzzer System (to alert personnel on the opposite side during material transfer): Incorporates an audible alert system for communication and safety during material transfer.

Intercom System: Enables seamless communication within the equipment or with personnel outside.

Fire-Rated (FLP): Equipped with fire-resistant features to enhance safety and prevent fire hazards.

Roller Conveyors: Integrates efficient roller conveyors for smooth material movement within the system.