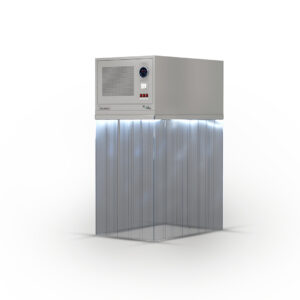

RLAF – Reverse Laminar Airflow

RLAF /Down-flow booths – Down Flow Booths are commonly used in powder handling applications because they effectively contain and control the spread of powders and dust. The laminar airflow system creates a “clean zone” within the booth, where powders and dust are captured and filtered before they can escape into the surrounding area. The downward flow of air also helps to prevent powders and dusts from becoming airborne and spreading beyond the booth. This makes the environment safer for the operators and also helps to maintain the purity and integrity of the powders being handled. The booth can be designed to handle different types of powders, such as pharmaceutical powders, food powders, and chemical powders, and can include features such as a HEPA filtration system, a pressurization system, and a sound-dampening system.

PIOUS ProtectAir : Protect Your Area with ProtectAir

- DESCRIPTION

- FEATURES

- WORKING PRINCIPLE

- MODELS

- ACCESSORIES

Revolutionize powder handling with our Down Flow Booths. These booths effectively contain and control powders and dust, creating a secure 'clean zone' through a laminar airflow system. The downward airflow prevents airborne particles, enhancing operator safety and preserving powder purity. Versatile and accommodating, these booths are tailored for various powders, from pharmaceuticals to chemicals. Optional features include a HEPA filtration system, pressurization, and sound-dampening for precision in diverse applications. Elevate your powder handling efficiency with our compact and advanced Down Flow Booths.

Recirculating air flow: The air inside the booth is filtered and recirculated to maintain a controlled environment.

Containment: The design of the booth provides a controlled environment with limited air exchange with the outside, making it ideal for use in applications where contamination control is important.

Three-stage filtration: in a Down flow Booth or RLAF (Reverse Laminar-Airflow) refers to the process of filtering air to maintain a controlled environment within the booth. The three stages of filtration are:

a) Pre-filtration: This stage is the first line of defence in removing large particulate matter from the air. It typically uses medium-efficiency filters, such as panel filters or bag filters, to trap larger particles.

b) Intermediate filtration: This stage provides an additional layer of filtration, removing finer particles and improving the overall air quality. Intermediate filtration typically to trap smaller particles.

c) Final filtration: This stage provides the final level of filtration, ensuring the air entering the booth meets the required air quality standards. Final filtration typically uses HEPA filters or ULPA filters.

Lighting: Lighting is usually provided within the booth to allow for easy observation and monitoring of processes.

Size and shape: RLAF or Down flow booths are available in a range of sizes and shapes to meet different application requirements.

User-friendly controls: The controls for the booth are usually simple and user-friendly, making it easy to operate and maintain the controlled environment.

The basic working principle of a down flow booth involves creating a downward flow of air within the booth to help prevent the release of hazardous particles and fumes. By forcing the air downward through filters, any hazardous particles or fumes are removed, and clean air is exhausted back into the surrounding area. The downward flow of air also helps to keep powders and dusts from becoming airborne and spreading beyond the booth, making the environment safer for operators. By controlling the flow of air, the down flow booth creates a controlled and safe environment for handling hazardous materials.

A Flame Proof Down Flow Booth or Reverse Laminar Airflow (RLAF) booth can be used to handle powders that are reactive to oxygen and may cause a fire. The booth provides a safe environment for handling these powders by controlling the airflow and creating a fire-resistant environment. The down-flow air pattern in the booth helps to keep hazardous particles contained, while the flameproof construction helps to prevent the spread of fire in the event of an ignition. Additionally, the booth is equipped with exhaust systems to safely vent any hazardous fumes, providing a safe environment for workers handling reactive powders.

Model Code | Internal Width (mm) | Internal Depth (mm) | Internal Height(mm) |

ProtectAir 303 | 900 | 900 | 2000 |

ProtectAir 403 | 1200 | 900 | 2000 |

ProtectAir 504 | 1500 | 900 | 2000 |

ProtectAir 604 | 1800 | 900 | 2000 |

Model Code | External Width (mm) | External Depth(mm) | External Height(mm) |

ProtectAir 303 | 1000 | 1550 | 2450 |

ProtectAir 403 | 1300 | 1550 | 2450 |

ProtectAir 504 | 1600 | 1550 | 2450 |

ProtectAir 604 | 1900 | 1550 | 2450 |

Customized sizes Available as per requirement | |||

Workstations: Workstations may be installed within the booth to provide a workspace for workers to perform their tasks.

Protective equipment: Workers handling hazardous materials within the booth may need to wear protective clothing, gloves, and other personal protective equipment (PPE).

Electrical and communication systems: This includes power outlets, data ports, and other electrical and communication systems that may be needed to operate equipment within the booth.

Yellow Light or Sodium Light: is commonly used in down flow booths or RLAF (Reverse Laminar AirFlow) booths when handling white light-sensitive powders. White light-sensitive powders can be affected by exposure to bright white light, which can cause chemical reactions, discoloration, or degradation. Sodium lights emit a yellow light that is less intense than white light and less likely to cause these issues. By using a yellow light, the risk of damaging the powder being handled is reduced, helping to maintain the integrity of the product.

A PVC (polyvinyl chloride) curtain: is often used in down flow booths or RLAF (Reverse Laminar Air flow) booths to provide a barrier between the interior of the booth and the surrounding area. The use of a PVC curtain in a down flow booth or RLAF booth helps to ensure a safe and controlled environment for workers handling hazardous materials.