Blog Details

Occupational Exposure Limits

Understanding Occupational Exposure Limits (OELs) and their

importance in the workplace

As an employer, it is your responsibility to ensure the safety of your workers, especially those who are exposed to hazardous chemicals and substances. One way to achieve this is by understanding and implementing Occupational Exposure Limits (OELs).

What are Occupational Exposure Limits (OELs)?

Occupational Exposure Limits (OELs) are defined as the maximum airborne concentration of a hazardous substance that an employee can be repeatedly exposed to for a specified duration without experiencing harmful effects. OELs are set to protect workers from developing occupational diseases caused by exposure to hazardous chemicals in the workplace.

Types of OELs and their measurement units

OELs can be measured in different units, depending on the physical form of the hazardous substance. For example:

- mg/m3: for metals and salts that do not form vapours at room temperature

- Fibres/cc

- PPM (Part per million): for a gas or vapour at normal room temperature and pressure.

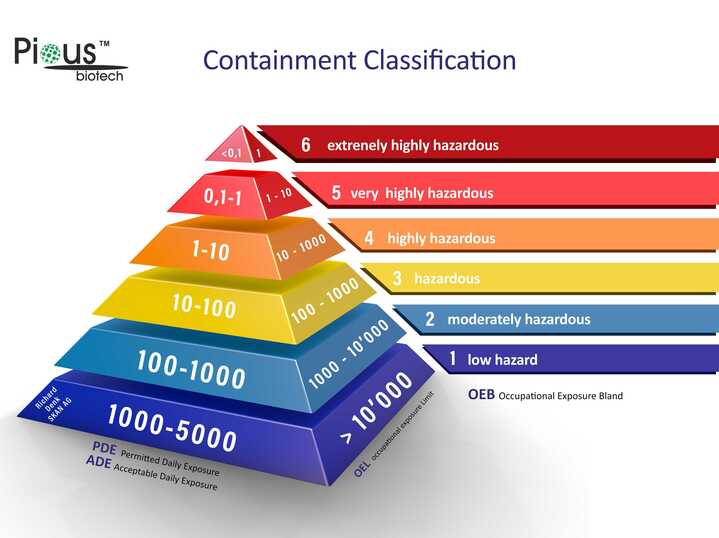

The following table shows some OEL values based on OEB banding:

|

OEB Banding |

OEL Level (mg/m3) |

|

1-2 |

10 |

|

3 |

1 |

|

4 |

0.1 |

|

5 |

0.01 |

|

6-7 |

<0.01 |

OEB banding is a general guide and should not be used as an exact science. Each application should be assessed independently and appropriate containment measures implemented.

Containment systems based on OEB banding

The following are some examples of containment systems that can be used based on OEB banding:

OEB band 1 to 2:

- Local exhaust ventilation

OEB band 3 to 5:

- Downflow booth

- Cone valves

- SBV (split butterfly valve)

OEB band 6 to 7:

- Barrier isolators (flexible and rigid)

- RTP (Rapid transfer ports)

Factors to consider when selecting containment measures

When selecting the appropriate containment measures, there are several factors that must be considered. These include:

- Product dustiness: The more dusty the product, the greater the risk of exposure.

- Type of product: Some products, such as cytotoxic substances, require extra precautions.

- The process: Certain processes, such as sieving or milling, can generate more dust than others.

- Duration of exposure: The longer the exposure, the greater the risk.

- Quantity of powder: Handling a large quantity of powder increases the risk of exposure.

Conclusion

Implementing appropriate containment measures based on OEB banding and understanding OELs are crucial in protecting workers from hazardous substances. By considering the factors mentioned above, you can ensure that your workers are safe and healthy while working with hazardous chemicals in the workplace.